Electricity is integral to every business operation ranging from office environments to industrial settings. However, when mishandled it poses significant risks leading to even fatalities highlighting the importance of electrical safety training. The following paragraphs offer a detailed overview of electrical safety training along with suggesting the common electrical hazards, the importance, aspects covered, and best practices in electrical safety training.

Table of Contents

- An Overview of Electrical Safety Training

- Common Electrical Hazards in Workplaces

- The Importance of Electrical Safety Training

- Key Areas Covered in Electrical Safety Training

- Best Practices for Electrical Safety Training

- Conclusion

- Infographic

- Knowledge Check!

- Frequently Asked Questions (FAQs)

- What is the importance of electrical safety training?

- What are the common electrical hazards in workplaces?

- What are the key areas addressed in electrical safety training?

An Overview of Electrical Safety Training

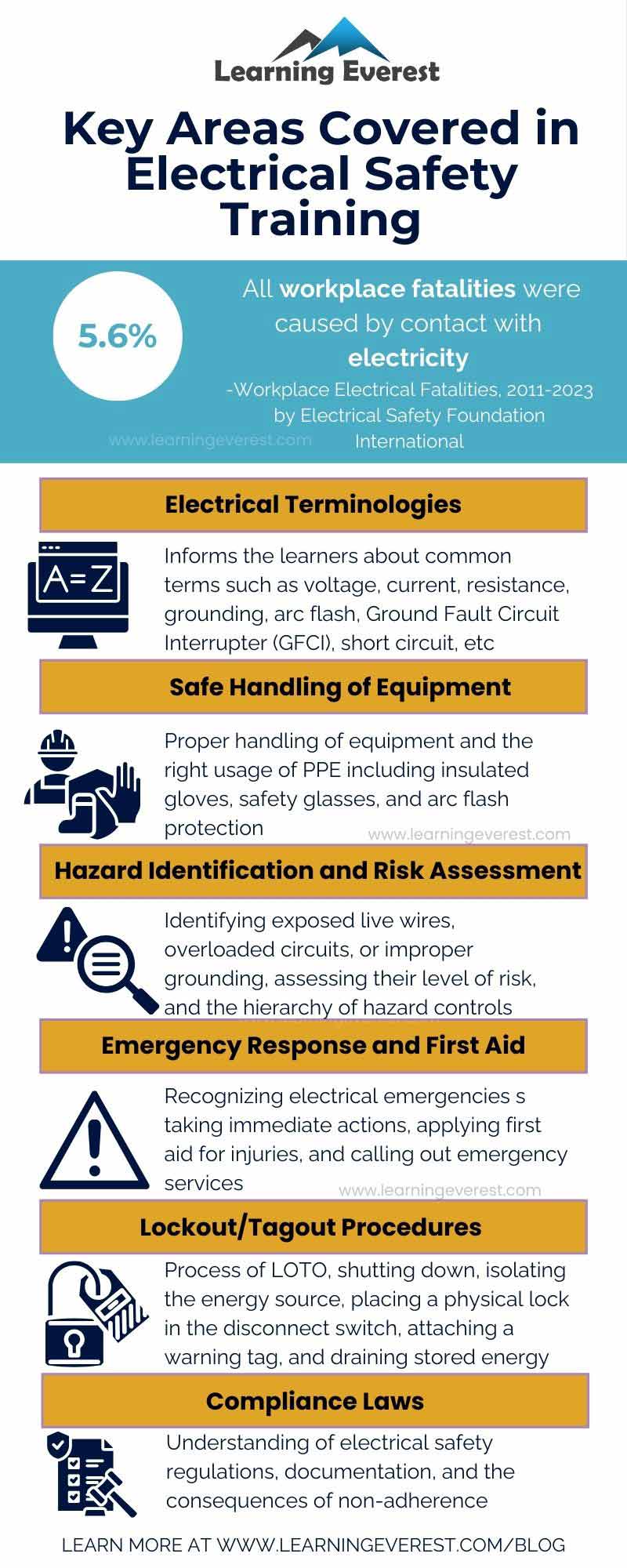

Electrocution is “considered one of the leading causes of fatalities in the workplace” and “5.6% of all workplace fatalities were caused by contact with electricity.” (Source: Workplace Electrical Fatalities, 2011-2023 by Electrical Safety Foundation International). Electrical safety training is a systematic program aiming at creating awareness, knowledge, and safe practices in handling, operating, and maintaining electrical systems. Incorporating electrical safety training in the workplace helps prevent injuries, risks, and fatalities due to electrical hazards.

Common Electrical Hazards in Workplaces

Understanding the common electrical hazards in the workplace is crucial before grasping the importance of electrical safety training. The major hazards include damaged equipment, frayed, loose, or exposed electrical cables, improper use of extension cords or power strips, exposure to wet conditions, high voltage in overhead powerlines, overloaded circuits, and arc flashes or explosions. These hazards can lead to injuries which include electric shocks, burns (arc burns, thermal burns, and internal burns), muscular injuries, cardiac-related issues, respiratory issues, blindness, deafness, traumatic injuries, and even cause fatalities.

The Importance of Electrical Safety Training

Since the common electrical hazards and their aftermath is a serious life-threatening issue, it is important to train all employees, supervisors, and employers to understand the need for electrical safety training. Offering electrical safety training at the workplace is crucial because of the following:

Importance of Electrical Safety Training

Prevents Workplace Accidents and Incidents

Training creates awareness of the safe usage of electrical equipment and systems, encouraging the learners to recognize dangers, take appropriate measures, and respond effectively to issues. In addition to preventing of incidents from taking place, the training offer knowledge to the employees on preventing minor incidents from escalating into major workplace disasters.

Legal and Regulatory Compliance

Providing electrical safety training to employees is a legal requirement for organizations as they need to comply with the safety standards of the Occupational Safety and Health Administration (OSHA). Failures to provide training leads to penalties, fines, and legal liabilities for the organization.

Productive and Well-Informed Workforce

Investing in electrical safety training rewards with highly productive and competent employees possessing skills and technical knowledge about safe electrical practices.

Reduce Downtime and Cost Issues

Apart from protecting employees and preventing hazards, electrical safety training plays a critical role in minimizing downtime and cost-related issues for businesses. Electrical hazards can lead to serious accidents and work stoppages leading to delays in project completion and loss of work hours.

Staying Up-to-Date

With advancements in electrical systems and safety technologies, employees need to be aware of how to utilize them. The participants of the electrical safety training program understand the latest protective equipment and tools and learn how to handle modern electrical systems safely.

Key Areas Covered in Electrical Safety Training

Electrical safety training prevents workplace accidents and empowers participants to recognize and report incidents. A well-structured training covers a wide range of topics addressed in different modules equipping the participants to handle electrical systems safely. The key areas to be addressed in every electrical safety training are:

Electrical Terminologies

When working with electrical systems, employees need to follow safety instructions and communicate clearly, emphasizing a critical understanding of electrical terminology. For instance, the training informs the learners about common terms such as voltage, current, resistance, grounding, circuit breaker, arc flash, Ground Fault Circuit Interrupter (GFCI), short circuit, etc. Incorporating a clear understanding of the terms helps in developing a clear picture of electrical systems and a more informed workforce.

Safe Handling of Equipment

Proper handling of equipment and the right usage of Personal Protective Equipment (PPE) including insulated gloves, safety glasses, and arc flash protection is necessary to prevent workplace is essential to prevent accidents and injuries. Electrical safety training covers the key areas of pre-use inspection including checking for damaged cords, plugs, and grounding, proper use of equipment, and safe storing of tools in designated organized areas.

Hazard Identification and Risk Assessment

Hazard identification and risk assessment is a key aspect covered in electrical safety training. Enriching the employees with the knowledge of potential dangers such as identifying exposed live wires, overloaded circuits, or improper grounding, assessing their level of risk, and the hierarchy of hazard controls eliminates workplace accidents from occurring.

Emergency Response and First Aid

“Safety starts with preparedness.” Another key area addressed in electrical safety training includes preparing employees with the knowledge of responding to emergencies and effective use of first aid. The training must address recognizing electrical emergencies such as electric shocks, electrocution, burns, and fires, and taking immediate actions involving not touching the victim directly, shutting off the power source, applying first aid for injuries, and calling out emergency services.

Lockout/Tagout Procedures (LOTO)

Lockout tagout is “a protection system against unintentional exposure to hazardous energy from equipment and machinery.” Electrical safety training must cover a comprehensive understanding of the purpose of LOTO, the process of LOTO involving preparation for shutdown, shutting down, isolating the energy source, placing a physical lock in the disconnect switch, attaching a warning tag, and draining stored energy, and employee responsibilities in LOTO procedures.

Compliance Laws

Along with equipping the employees with skills in electrical safety, informing the compliance requirements is essential to promote a culture of safety. The aspects covered should incorporate a detailed understanding of major electrical safety regulations put forward by OSHA and NFPA, documentation of compliance measures, and the consequences of non-adherence to the regulations.

Best Practices for Electrical Safety Training

For ensuring the utmost effectiveness of the electrical safety training, simply delivering training is not enough. The program should be crafted effectively to ensure the participants apply the principles and their learning in real workplace situations.

The best practices involve the program aligning with the compliance standards set by local, national, or international safety regulatory bodies, offering personalized training based on the industry, role, learning style, and need of the learner, providing engaging and interactive training incorporating scenarios, simulations, hands-on practice, demonstrations, and role plays for improved retention, encouraging practical evaluation strategies and feedback, promoting a safety-first culture, and ensuring active participation of the learners in the learning process. Implementing these best practices ensures the effectiveness of the training in equipping the employees with safety skills.

Conclusion

Electrical safety training aims at creating awareness, knowledge, and safe practices in handling, operating, and maintaining electrical systems. It is important to adopt the training in workplaces to prevent workplace accidents and incidents, as part of adhering to legal and regulatory compliance, creating a productive and well-informed workforce, reducing downtime and cost issues, and staying up-to-date.

The key areas addressed in the training include electrical terminologies, safe handling of equipment, hazard identification and risk assessment, emergency response and applying first aid, Lockout/tagout procedures, and compliance laws. Prioritizing electrical safety training is therefore an investment in both employee well-being and business success.

Engage your teams with interactive and effective electrical safety training. Connect with us now!

Infographic

Key Areas Covered in Electrical Safety Training

Knowledge Check!

Frequently Asked Questions (FAQs)

What is the importance of electrical safety training?

It is important to adopt electrical safety training in workplaces to prevent workplace accidents and incidents, as part of adhering to legal and regulatory compliance, creating a productive and well-informed workforce, reducing downtime and cost issues, and staying up-to-date.

What are the common electrical hazards in workplaces?

The major hazards include damaged equipment, frayed, loose, or exposed electrical cables, improper use of extension cords or power strips, exposure to wet conditions, high voltage in overhead powerlines, overloaded circuits, and arc flashes or explosions.

What are the key areas addressed in electrical safety training?

The key areas addressed in the training include electrical terminologies, safe handling of equipment, hazard identification and risk assessment, emergency response and applying first aid, Lockout/tagout procedures, and compliance laws.